The machine is useful for product and industrial designers since it will not only help them implement their ideas faster, but it will also help create low-cost fast molds for art, medical, automotive, and aircraft industries. We believe that the work developed is novel since it combines emerging mold shape pixels adaptation with convention vacuum forming technology.

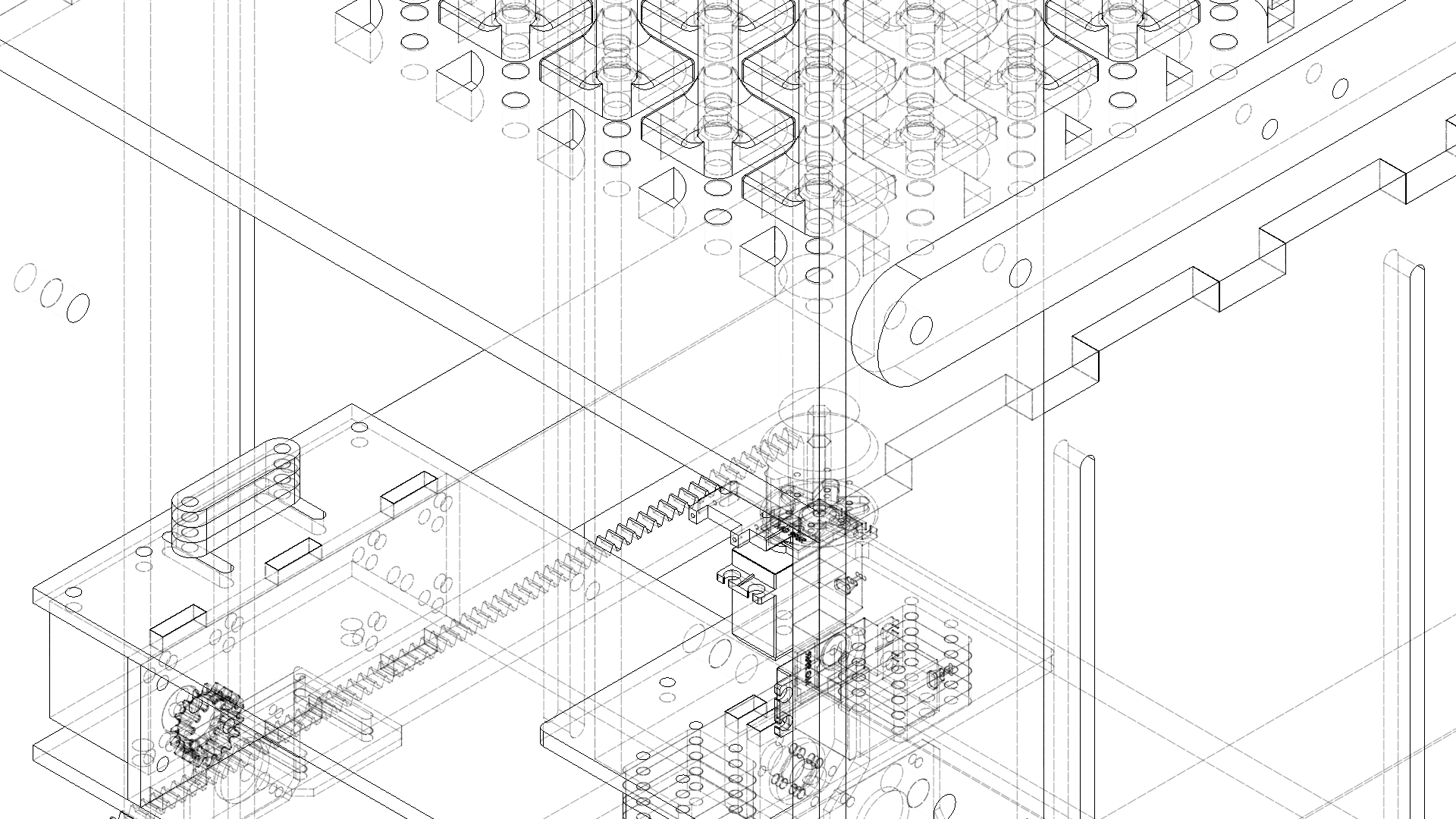

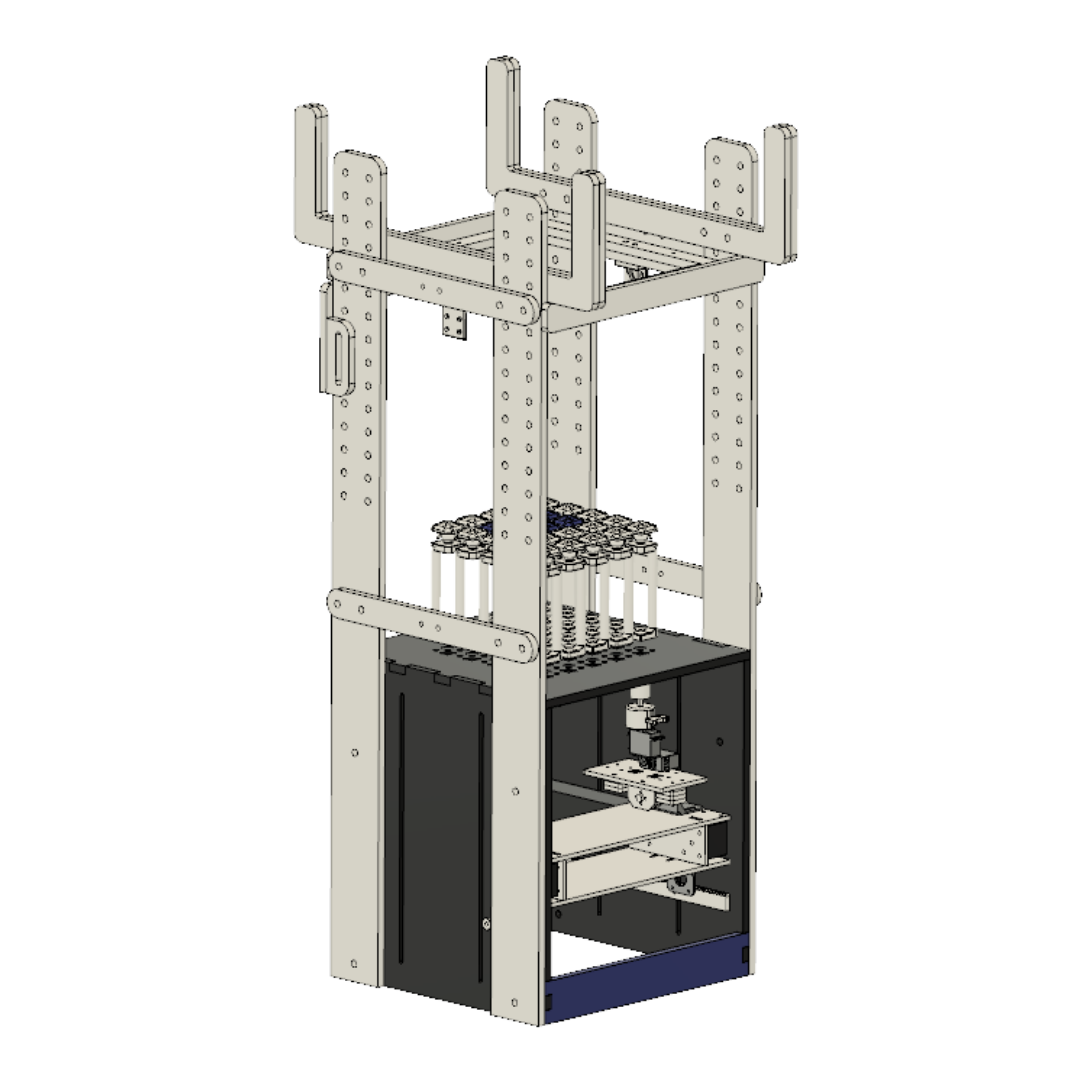

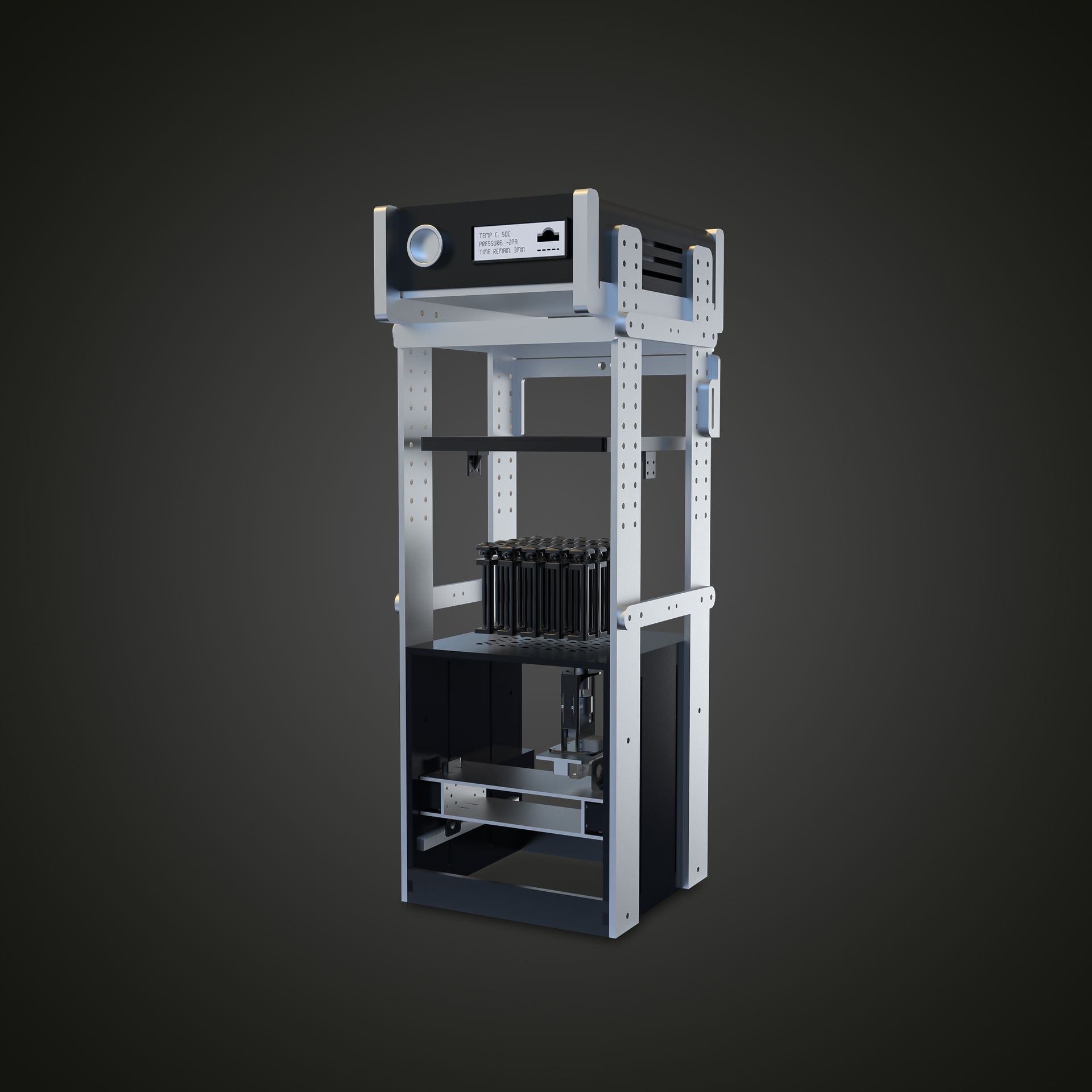

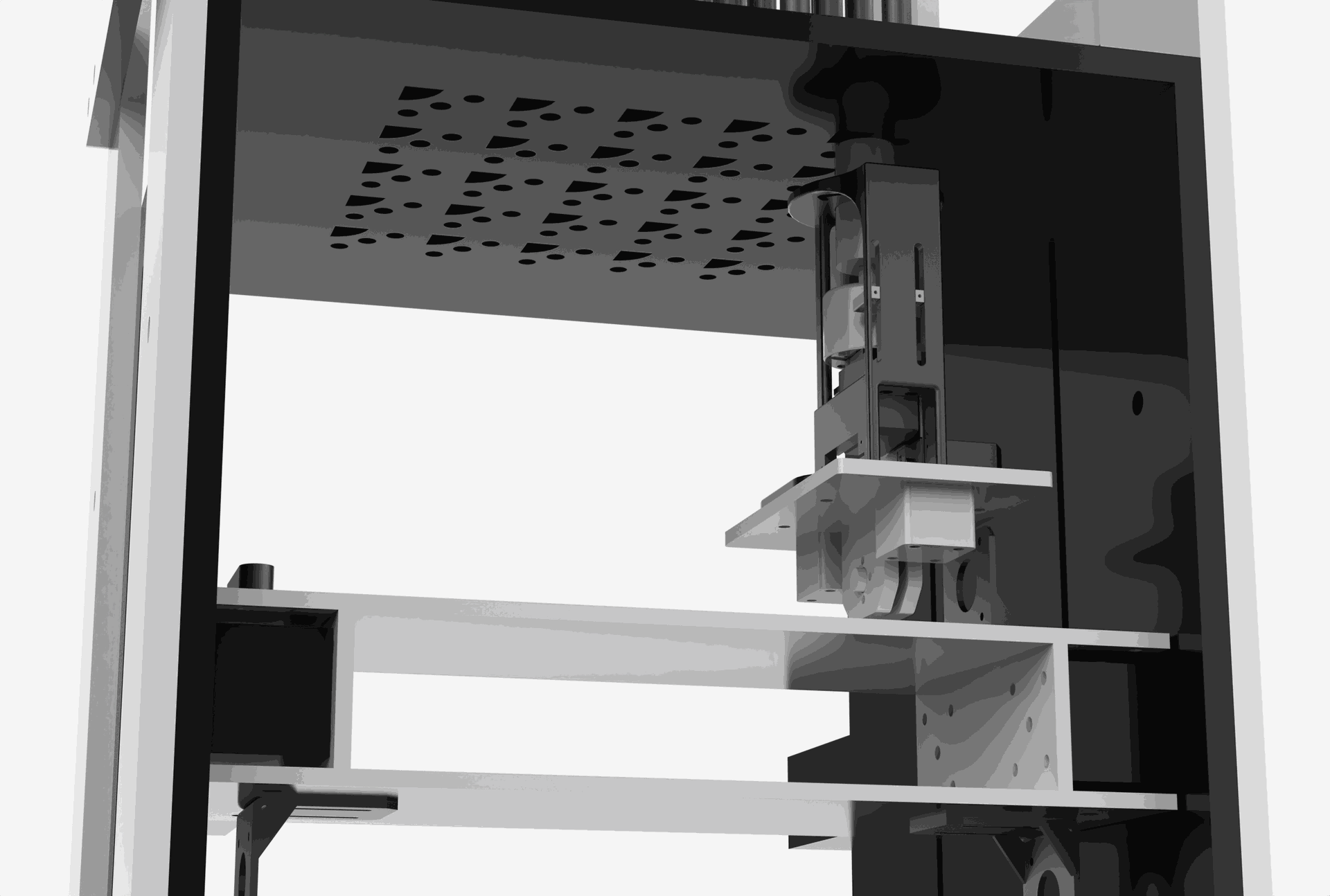

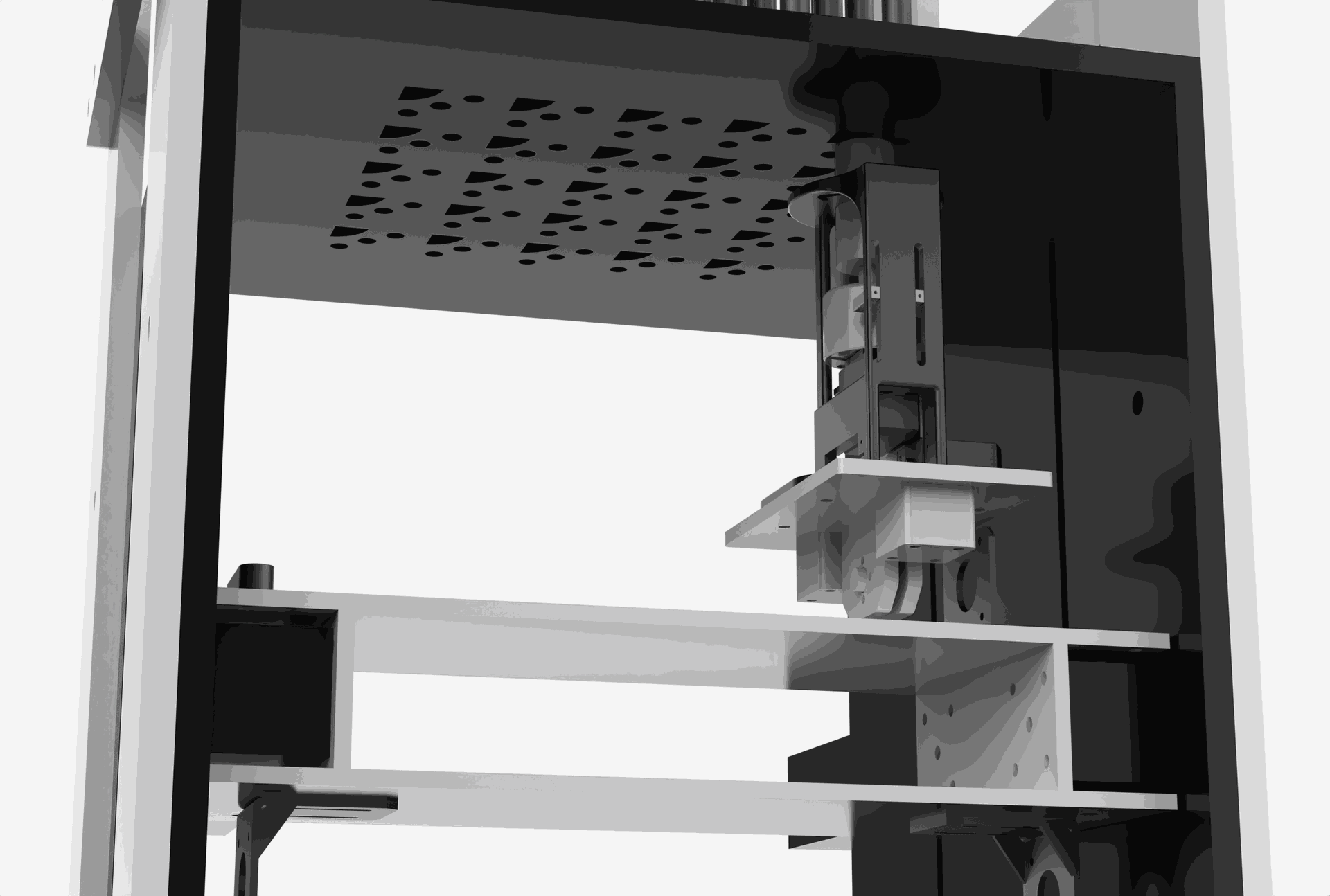

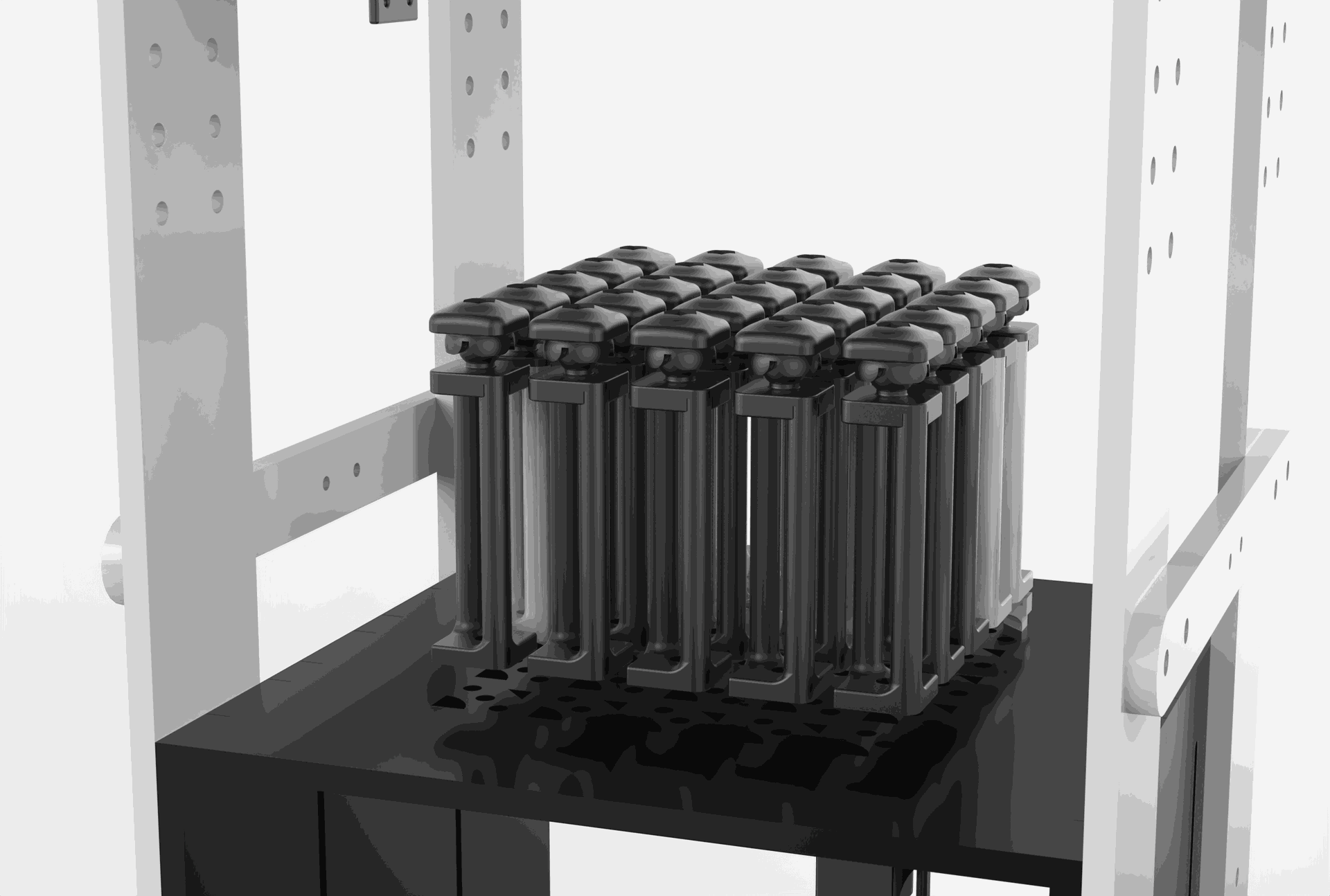

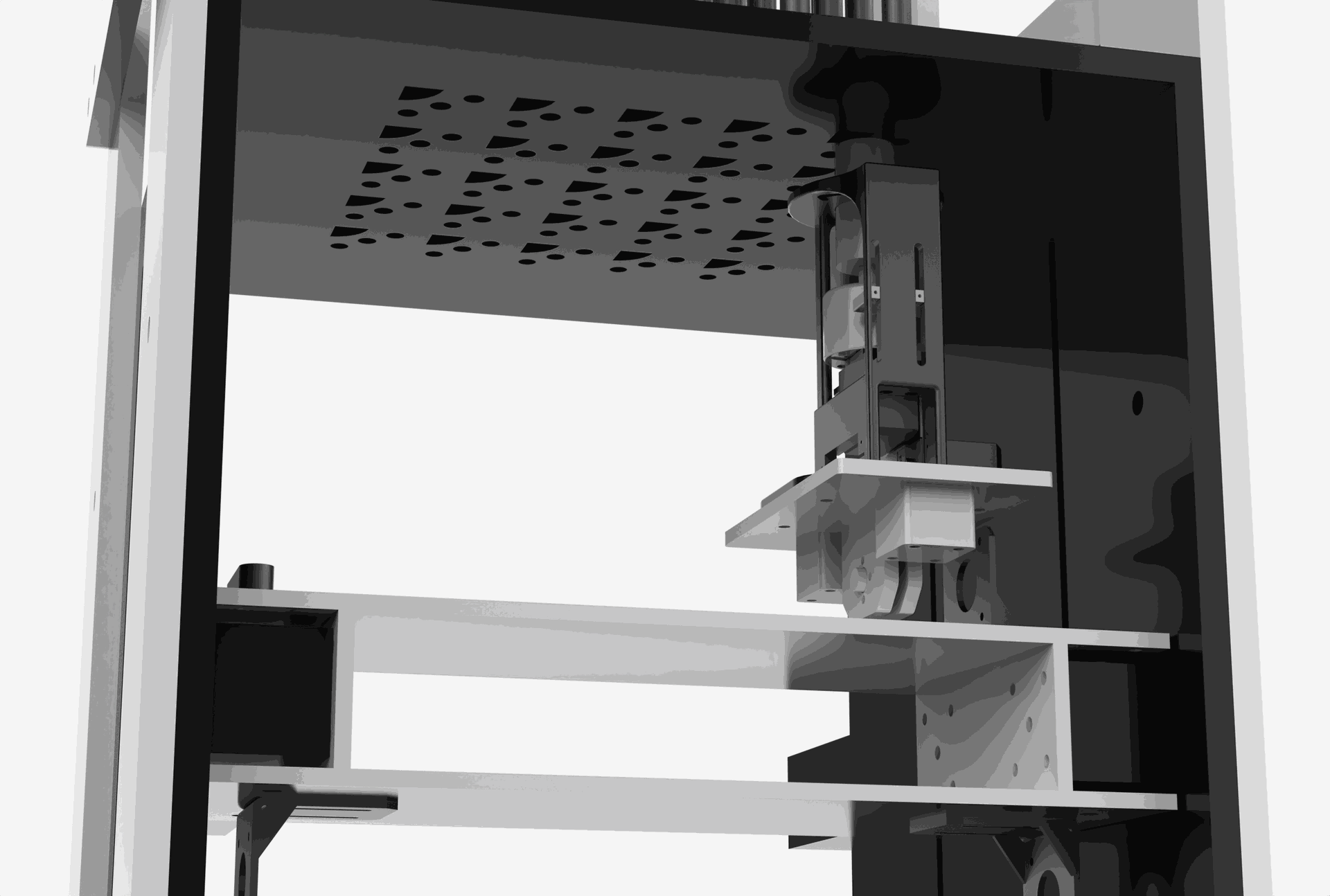

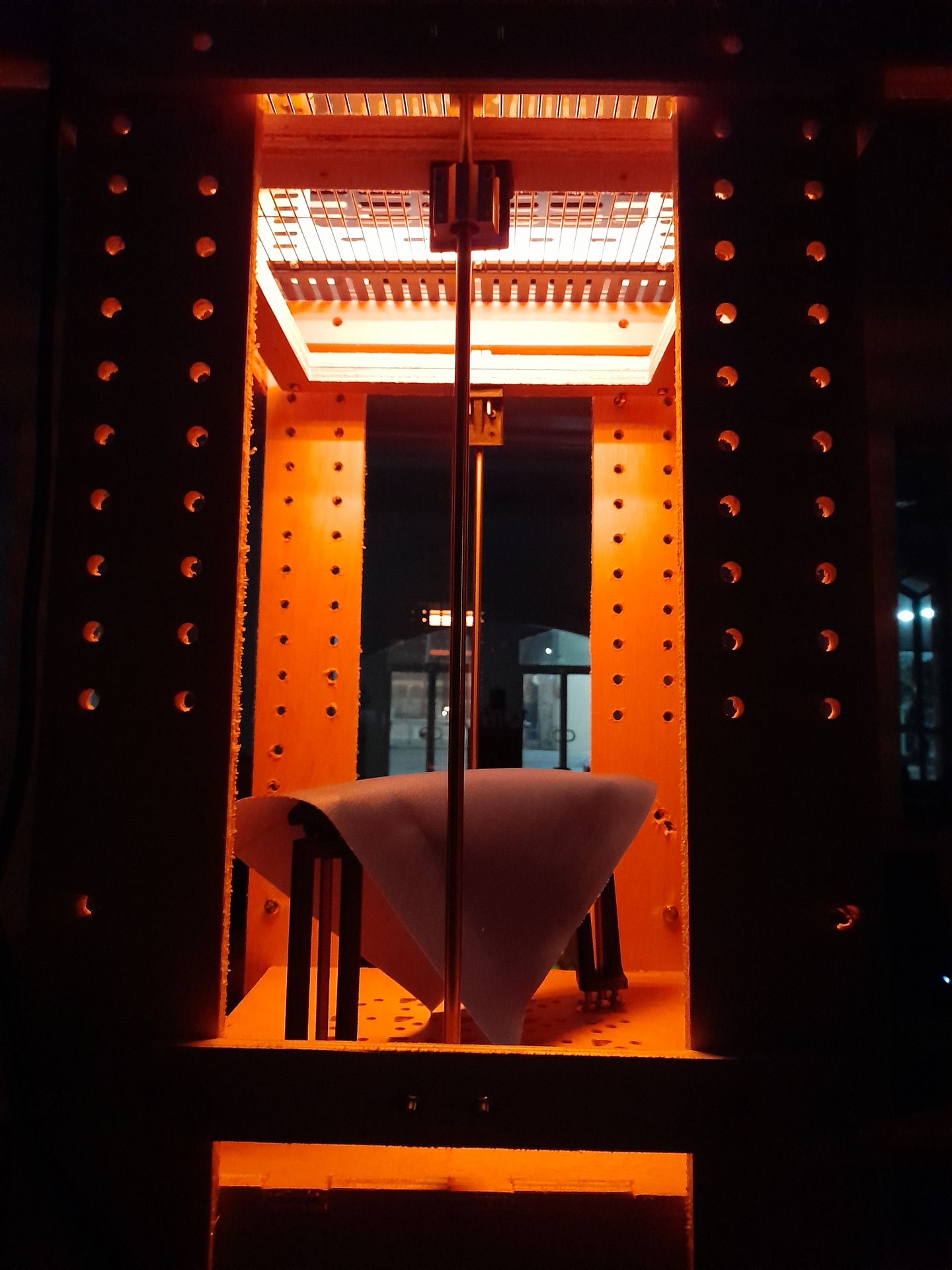

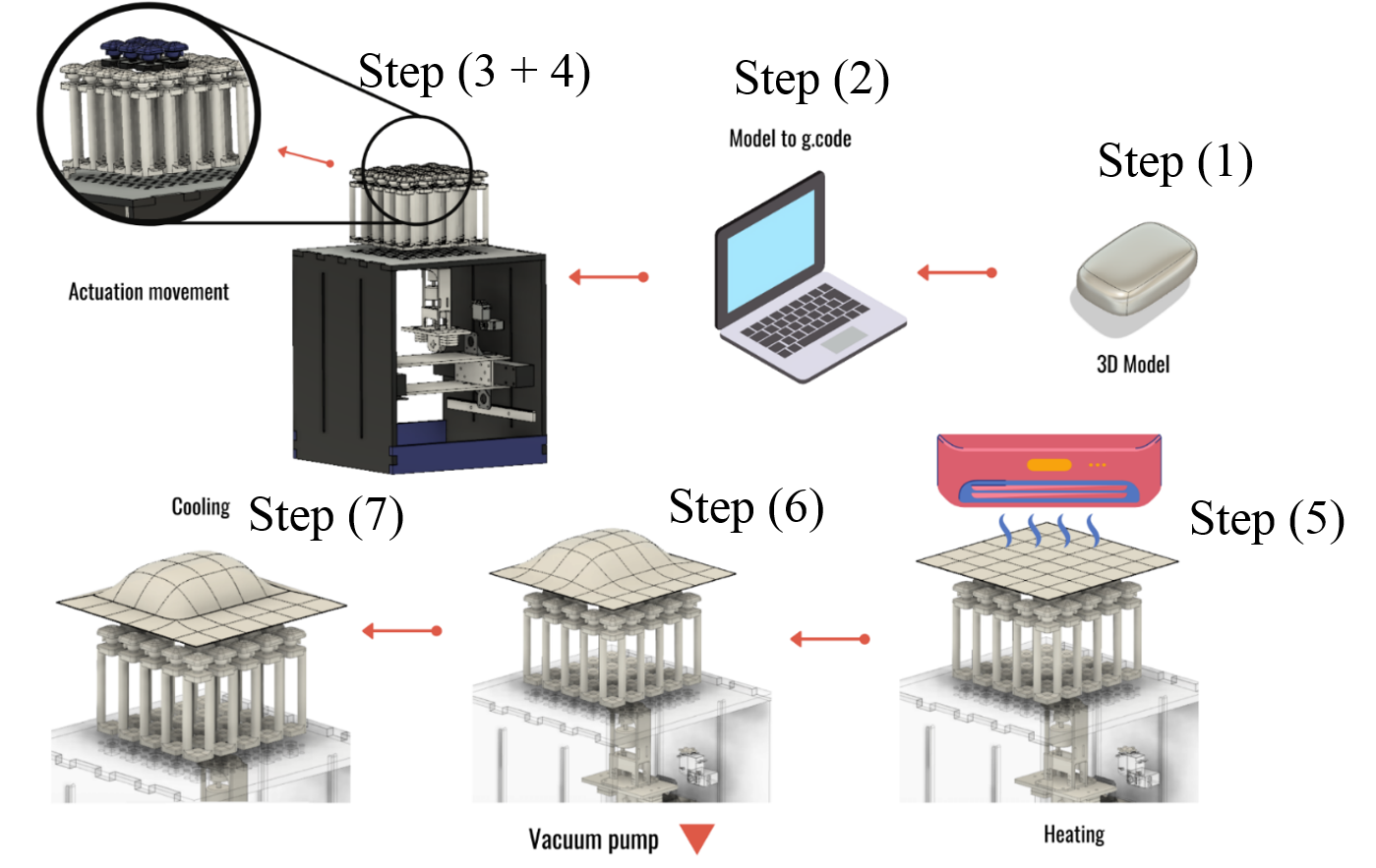

The machine can be used to create molds for art, medical, automotive, and aircraft industries using an adaptive mold. The objective of the project is to design a molding unit based on mold shape pixels position adaptation and vacuum forming technology. I locally designed and built the main components of the unit, which consists of pins actuating layer an interface layer, and a heating layer. An appropriate adaptation software is developed to convert the desired 3D digital mold shape to pixels' desired positions (set points). These latter are generated by the computer and sent to microcontrollers based on/off controllers on the actuating CNC layer used to adjust the pin's height at the desired height. The positions and curving are sensed using Hall Effect and ultrasonic sensors respectively. Once the position of the pins is adjusted, the remaining part of the unit will reproduce the mold shaped by the pins using heating and vacuum forming technology.

The features that make this machine very useful are:

- Scalability: the machine design allows the user to scale up the bed size by replicating some of the machine parts which will enable the user to manufacture bigger parts.

- Fabrication of a variety of shapes Can be used for the vacuum forming process.

- Fast: relatively faster than modern CNC milling which takes a long time to mil the material block.

- Cost-effective: By adjusting the height of the pins we can make molds without wasting the material that will be carved.

- Fabrication: The digital design of the machine allows it to be reproduced in any digital fabrication lab in the world.

- Units: The machine that we are building consists of many units stacked above each other which saves space and can be used in any fabrication lab due to the simplicity, small size, and portability.