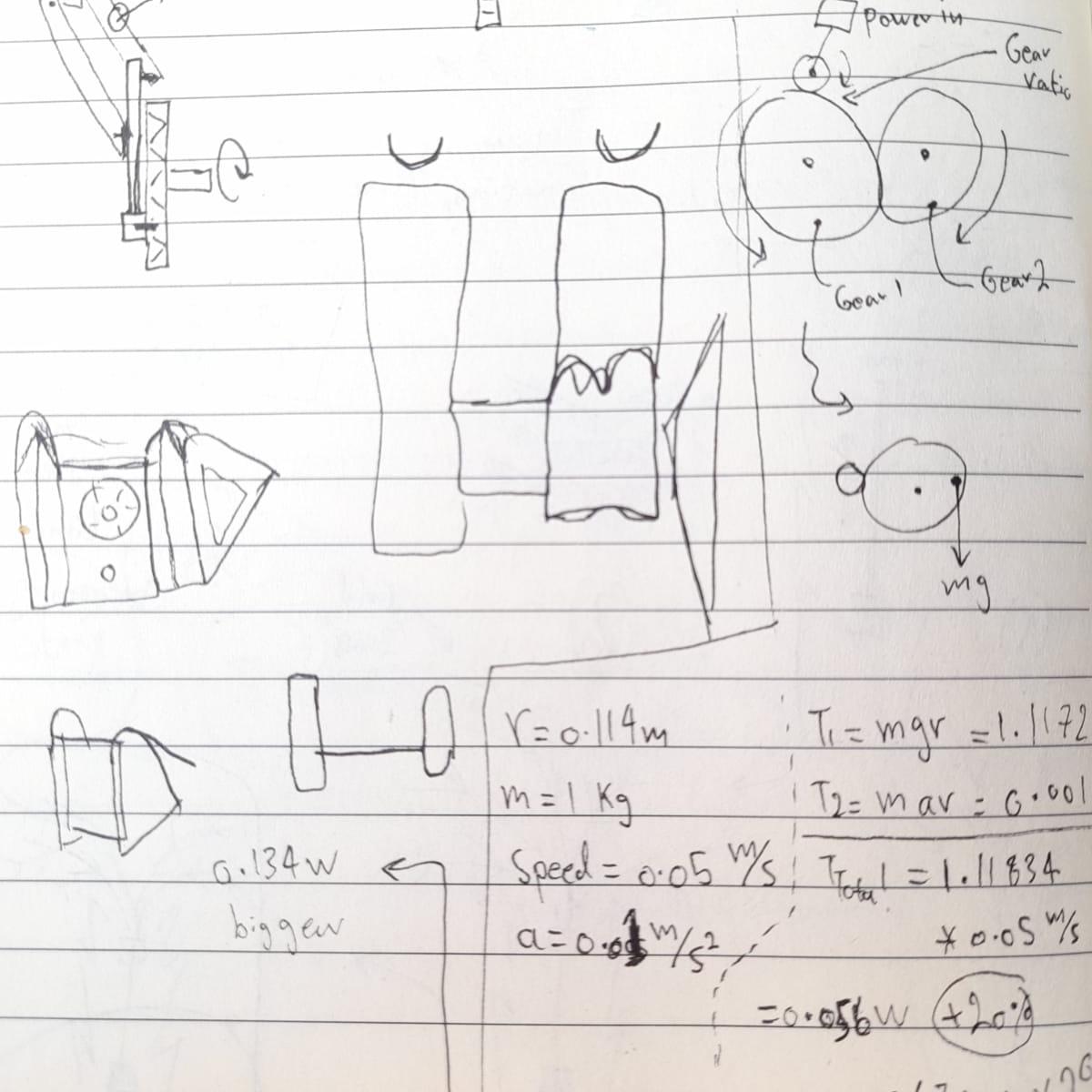

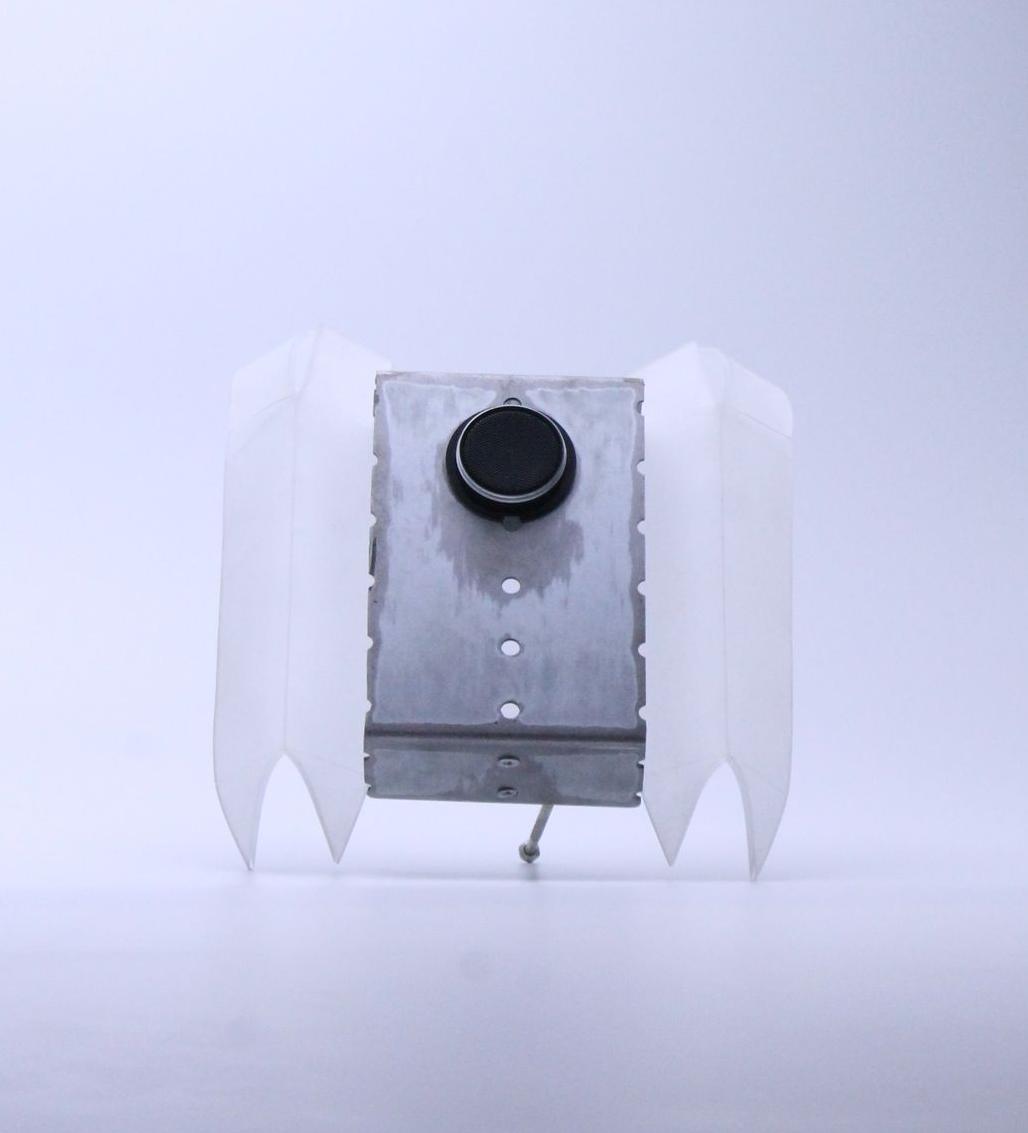

The form idea came to me when I was thinking about transforming 2D cuts into 3D forms. Inspired by the angles wings I designed and built a Bluetooth speaker.

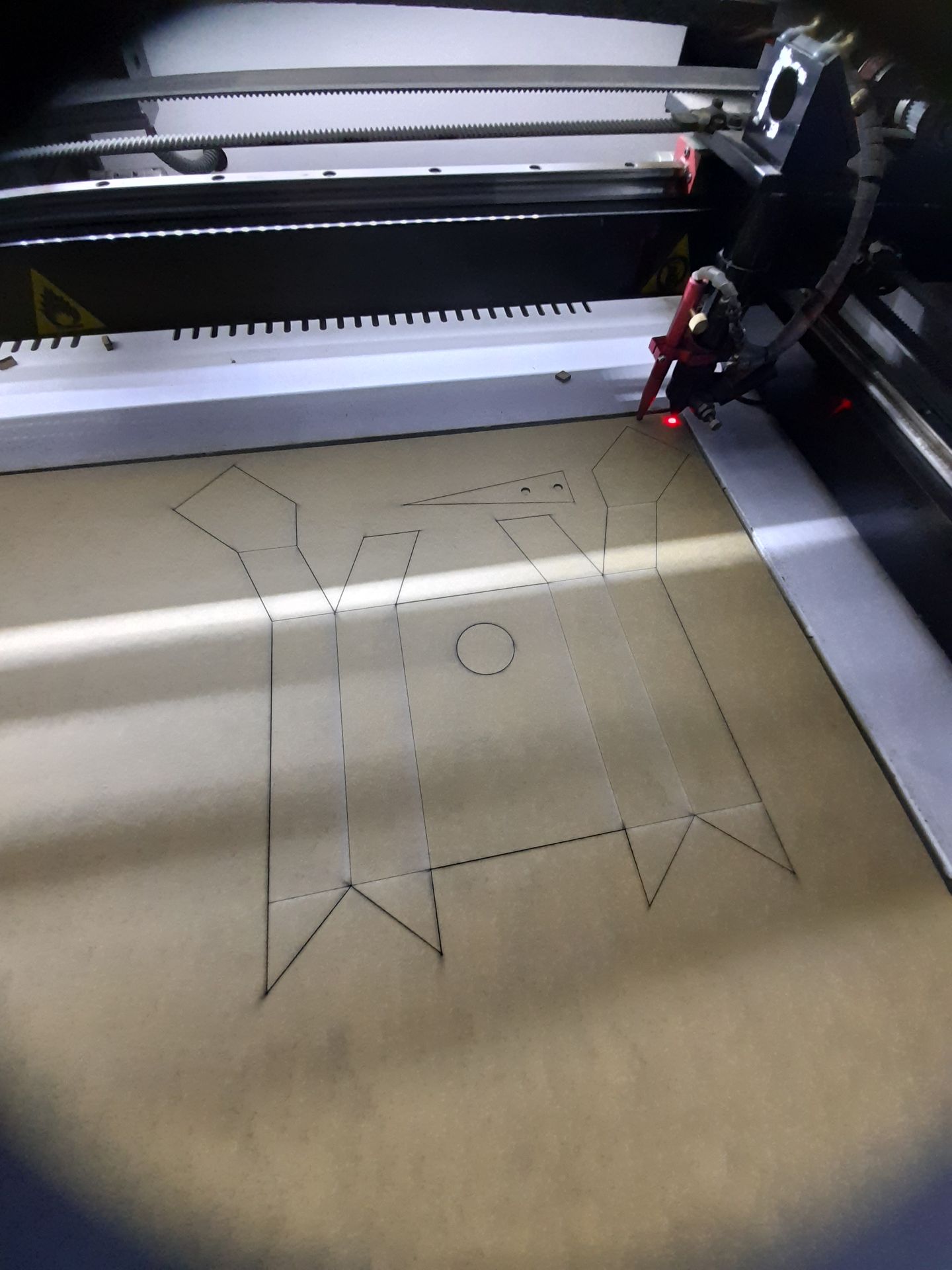

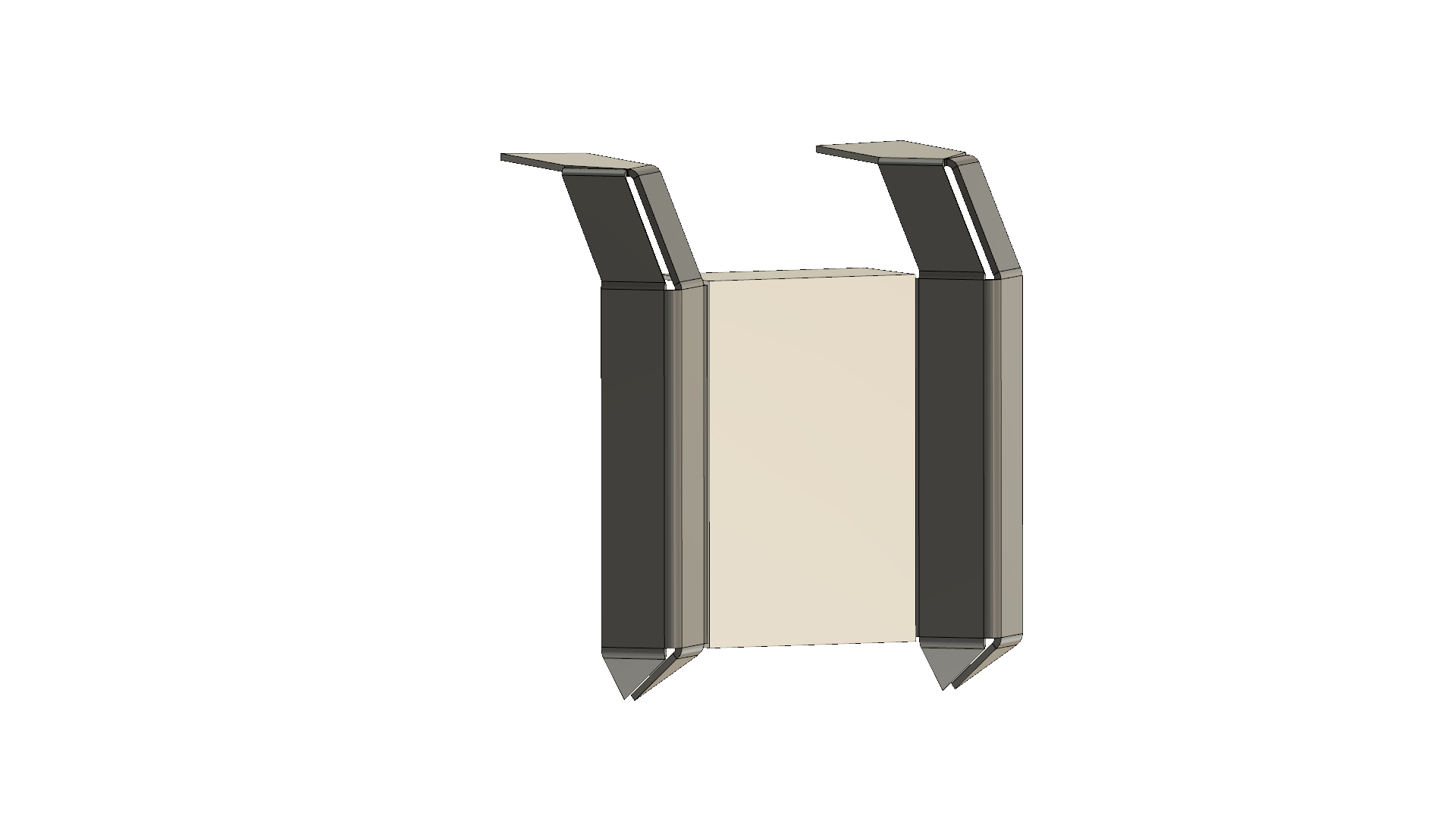

I wanted to test the process of designing a 3D object, transforming it into a 2D design, then fabricating the parts using a 2D tool, and finally shaping it to its 3D form. While designing I used ratios between the parts to set the form dimensions and Fusion 360 sheet metal tool. I also wanted to test combining different materials such as galvanized steel and frosted acrylic. Moreover, I wanted to test finishing techniques and combine a variety of fabrication processes.

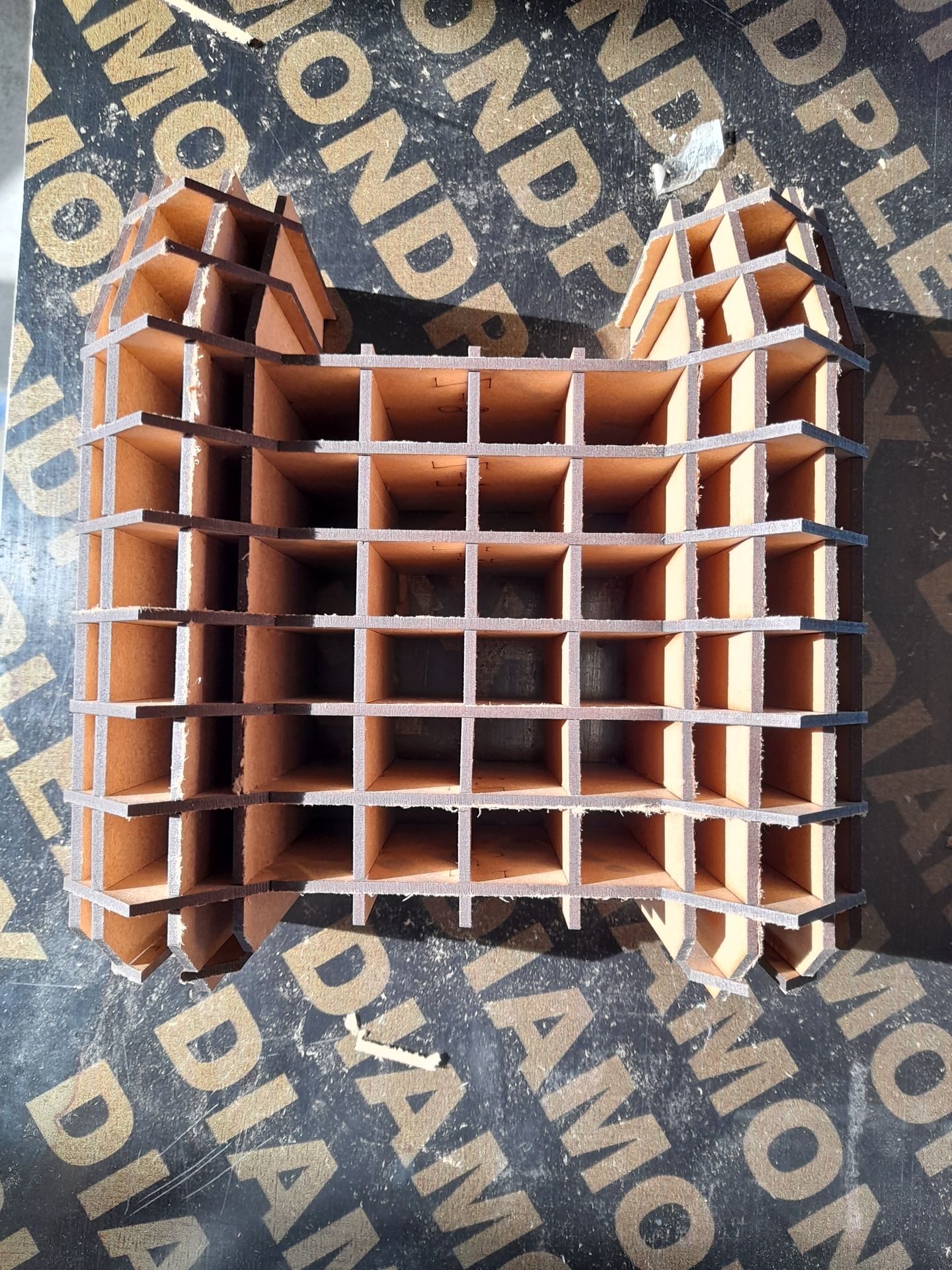

I started by slicing the 3D mold into a 2D design to laser-cut the mold parts. Then, I laser-cut the acrylic and sanded it to give it a frosted acrylic look. After that, I heated the acrylic using an oven and shaped it into the mold. Finally, I bought a galvanized steel section from the scrap yard and cut a small section of it, sanded it, and spray it with a clear coat to give it a smooth texture.